In this process, a separating/sealing membrane (master bag) is fixed within the pressure vessel. The powder is poured into the mold externally, then inserted into the pressure vessel with/onto the bottom. The isostatic pressure of the pressure fluid (hydraulic oil) is then applied to the outer surface of the mold via the built-in sealing membrane (master bag), compressing the powder into a solid part with a homogeneous microstructure.

Dry bag technology is ideal for mass production of parts.

The advantages of an isostatic dry die press:

Fully automatable

Reduced cycle times due to simultaneous filling / pressing / demolding / cleaning

Uniform strength and density

Homogeneous microstructure

Uniform shrinkage

High dimensional accuracy

Reduced finishing

Low mold cost

Wide variety of materials

Very high compacting pressures

Ideal for series and mass production

Modular system of process individual stations (basic version with later expansion / Expansion option available)

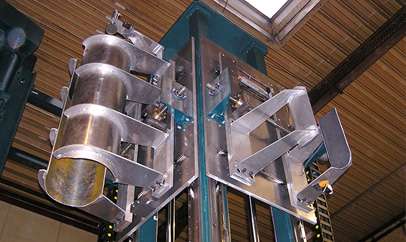

- Modular system consisting of individual process stations:

- Basic version – press station with hydraulic system, automatic controls, mold turntable with manual filling and demolding station

- Full version with fully automatic filling/demolding/cleaning and mold exchange station

- Press pressures up to 250 MPa (2,500 bar) in quick-release closure – threaded design (> 250 MPa as yoke version)

- Pressure vessel inner diameter: from 100 mm to over 600 mm

- Pressure vessel working lengths: from 300mm to over 2,000mm

- Variable press parameters for pressure build-up speed / pressure dwell time / decompression / holding or switching stages

- Selection of different high-pressure generators (high pressure multipliers / high pressure triplex plunger pumps / high pressure axial piston pumps

- Freely programmable high pressure decompression valve (servo-controlled) enables precise and variable decompression levels or decompression control via single-stroke pressure intensifier

- Storage of product-specific pressing parameter recipes

- Easy operation via plain text instructions

- Clear process displays

ISOSTATIC LABORATORY PRESSES – as wet and dry bag presses

Cutting-edge technology in a small format

LOOMIS PRODUCTS isostatic laboratory presses are the ideal solution for process/material testing and the production of smaller series.

Custom sizes available

Variable press parameters for pressure build-up speed / pressure holding time / decompression / holding or switching stages

Lifting and closing mechanism for the upper closure

Automatic de-airing valve

Fast pre-filling and emptying of the pressure vessel via high-volume pilot operated check valve

Adjustable high pressure decompression valve enables gentle and variable decompression

Selection of different high-pressure generators (air-driven high-pressure pump / hydraulic pressure intensifier

Easy operation via plain text instructions

Clear process displays