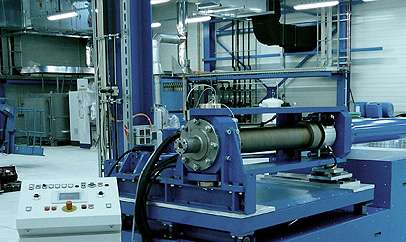

Piston extrusion – for uncompromisingly good products

Shaping in perfection: LOOMIS PRODUCTS piston extrusion presses meet the highest requirements for extruding pasty masses into tubes, rods, honeycomb bodies and other profiles.

Advantages of piston extrusion presses compared to screw extruders.

Low wear even with abrasive products

Very low maintenance costs / times

Minimal wear, thus hardly any contamination of the product by abrasion particles

No structure transfer in the product

Problem-free processing of porous, shear-sensitive masses

No pulsation of mass

No re-extrusion of the mass

Very high pressing forces

Easy start-up / cleaning without loss of mass

Ideal for laboratory use

The extruders can be supplied in various versions with a pressing force of up to over 6,300 kN (630 tons).

Application-optimized –

thanks to double tilt system or side-swing function

The Double Tilt system allows both the cylinder and the press frame to be hydraulically swiveled independently between 0° (horizontal) and 90° (vertical) to set the optimal loading and most efficient extrusion position .

The Side-Swing system allows the press to be automatically loaded with prefabricated hubs and enables extrusion positions of up to 45°.

Construction / Features:

- Standard configurations: 120 – 6300 kN (12 – 630 tons) press force

- Version in single/double tilt or side swing system

- Bulk material cylinder (barrel) sizes according to customer requirements

- Energy-efficient, servo-controlled hydraulic systems

- Adjustable / regulated extrusion pistons speeds from 0.001mm/s

- Variable extrusion pressure control

- Mass pressure gauge

- Integrated vacuum systems

- Hard chrome-plated material cylinders (barrels)

- Storage of product-specific pressing parameter recipes

- Data collection / storage

- Interfaces to cutting and conveying systems

- Easy operation via plain text instructions

- Clear process displays

- Minimal maintenance

- Easy tool change

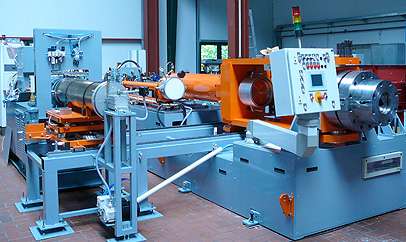

Small but mighty:

Our laboratory piston extrusion presses

The intelligent solution: Equipped with LOOMIS PRODUCTS cutting-edge technology, our laboratory piston extrusion presses are ideal for process/material testing and the production of small batches.

Construction / Features:

- Standard configurations: 160 – 250 kN (16 – 25 to) press force

- Version in single-/double-tilt system

- Bulk material cylinder (barrel) sizes according to customer requirements

- Energy-efficient, servo-controlled hydraulic systems or high-quality standard hydraulics

- Adjustable / regulated extrusion pistons speeds from 0.001mm/s

- Variable extrusion pressure control

- Mass pressure gauge

- Integrated vacuum systems

- Hard chrome-plated material cylinders (barrels)

- Storage of product-specific pressing parameter recipes

- Data collection / storage

- Interfaces to cutting and conveying systems

- Easy operation via plain text instructions

- Clear process displays

- Minimal maintenance

- Easy tool change